Hot products

Tel:0086- 166 5317 7104

E-mail:sales01@lanbaopm.com

The Discharge Dampener:

The discharge chamber or pulsation dampener, contrary to the suction dampener, is partly pressurized with nitrogen gas. During the discharge stroke the gas in the pulsation dampener is compressed. At the end of the discharge stroke the compressed gas expands sustaining a reasonable steady flow in the discharge line and dampening the peaks in discharge pressure.

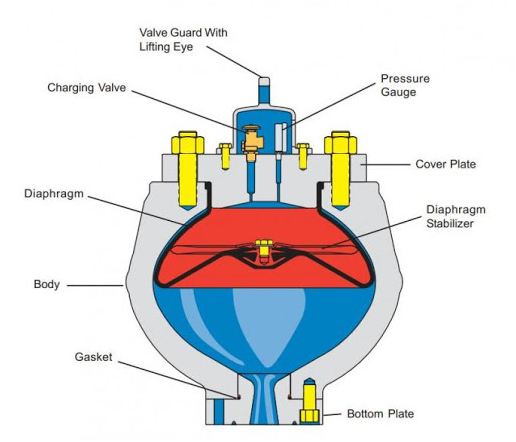

Below pix shows a commonly used pulsation dampener. It consists of a steel spherical body in which a diaphragm is fitted. The diaphragm separates the gas (nitrogen) from the drilling fluid.

A charging valve and a pressure gauge are installed on top of the pulsation dampener cover to allow regular inspection and recharging. To achieve a satisfactory dampening effect the pre-charge pressure should be 75% of the minimum anticipated pump operating pressure. The maximum pressure should not exceed 5250 kPa (750 psi).

WARNING: It is of the utmost importance that nitrogen only is used to charge the pulsation dampener. Serious accidents have been the result of using oxygen instead of nitrogen.